Zalkin is dedicated to safeguarding our customers while minimizing secondary microplastics and conserving energy resources. Our goal is to promote sustainable and secure technology by curbing plastic pollution, upholding product integrity, and reducing energy consumption. Through ongoing innovation, we tailor our products to align with customer-driven environmental initiatives.

In addition to supporting our customers’ environmental endeavors, Zalkin is actively implementing strategies to reduce plastic waste and microplastics through customized developments with cap and packaging manufacturers. This effort includes enhancing our tethered caps and aluminum bottle capping capabilities, as well as eliminating microplastic particles from caps before they enter the capper.

Tethered Caps

Zalkin, a global leader in capping machinery, possesses significant expertise in tethered closures, tailored for the beverage sector. Collaborating closely with cap producers and beverage companies, Zalkin has successfully integrated tethered cap solutions onto more than 100 capping machines, whether refurbished or newly installed.

Aluminum Bottles

Aluminum packaging helps mitigate environmental impacts by promoting the re-use of containers, recycling, and conserving resources compared to alternative packaging materials.

Zalkin’s proven roll-on capping heads are recognized throughout the wine, spirits and beer industries as best-in-class and they are known for their consistent, dependable performance. Like all Zalkin capping heads, roll-on sealing heads are compatible with Zalkin freestanding rotary cappers, monobloc rotary capping turrets and single head freestanding cappers.

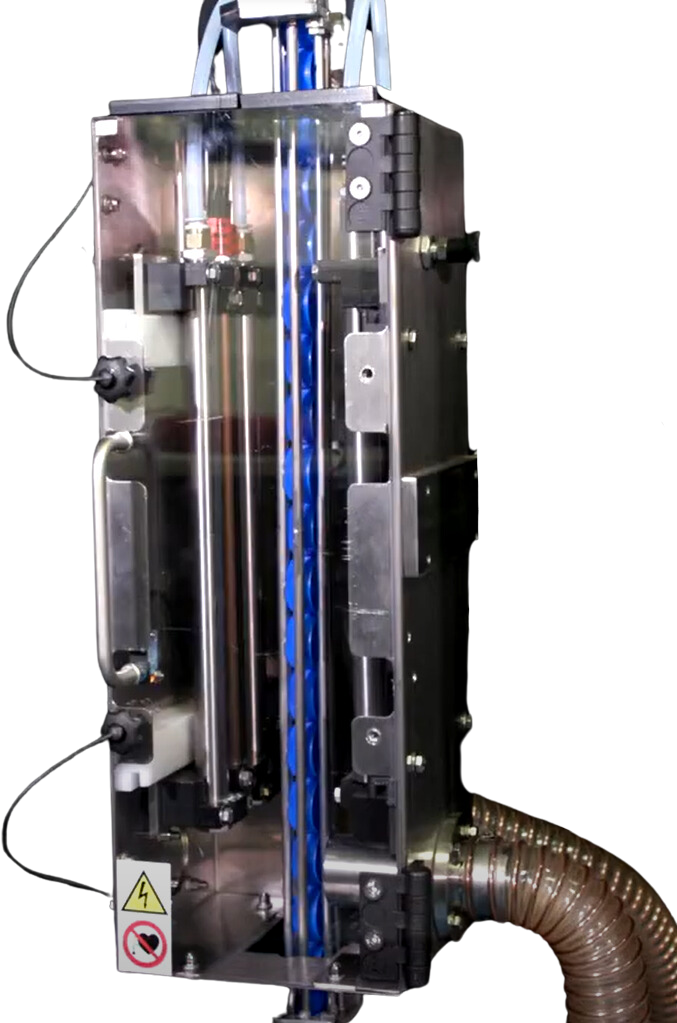

Dedusting

The water industry has become increasingly sensitive to the possible transfer of plastic particles and contamination to products.

Zalkin’s cap dedusting system is easily integrated into your existing line, whether it includes a Zalkin capper or another brand, and offers peace of mind for customers that want to enhance product quality. Our 3-step implementation includes audits, laboratory testing, and equipment for reducing contaminates to your products.

Key Features:

- Exposure time is 10 times greater than existing solutions

- Dual action ionizing bars for internal and external areas of closure

- Optimized management of flows for a maximal efficiency with double suction

The dedusting system is effective for any application requiring dust removal.