The oriented cap handling solution offered by Zalkin in a “Plug & Work” version (on a skid) is a modular and autonomous system: it can integrate sequentially any of our cap handling systems. At Drinktec, three of our new generation high speed equipment will be showcased on this skid: waterfall Z-Cascade, ZC-Prism cap inspection module and Z-Horizontal buffer.

Z-Cascade: new generation of high speed compact waterfall

Adapted to tethered caps and non-attached closures, up to 120,000 caps/hour, it is designed to be floor-mounted or on a platform, for an easy access during production and maintenance.

It is equipped with an autonomous control system.

Product integrity

– Gentle cap handling with less cap stirring

– Cap selection with electrically adjustable swing device

– Elimination of static electricity (chain with limited cap friction)

– Pulsed air filtration in closed loop (less plastic particles rejected in the surrounding environment)

Continuous operation

– Cap recirculation in the storage bin, without jamming risk – no start/stop of the system

Energy-efficient

– No compressed air needed

ZC-Prism for cap inspection

The oriented cap Pre-Inspection Module s a great addition to Z-Cascade and Z-Horizontal Buffer for an even better production quality.

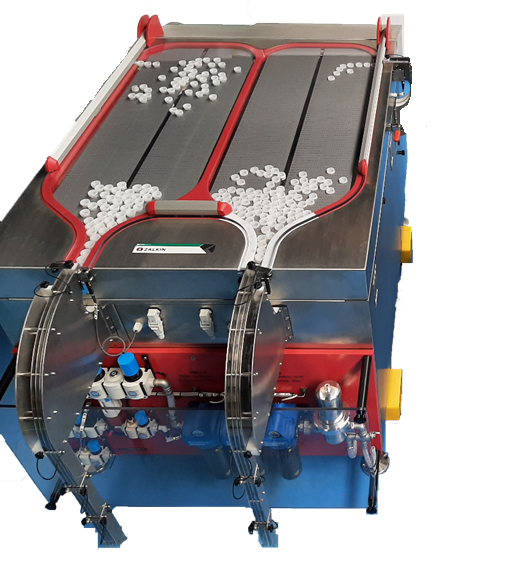

Z-Horizontal Buffer for high speed cap accumulation

Adapted to tethered caps and non-attached closures, up to 120,000 caps/hour, it is designed to be floor-mounted or on a platform, for an easy access during production and maintenance.

It is equipped with an autonomous control system.

Gentle cap handling

– Limited cap friction and closure deformation

– Bulk accumulation of the caps and realignment without mechanical device

– Anti-jamming system via air jets

Optional air quality treatment can be added for both equipment operating with pulsed air:

– Filters to increase the particles filtration performance

– Dedusting system

– Filtration system for air quality treatment